|

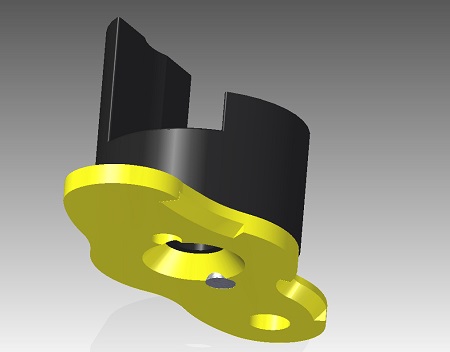

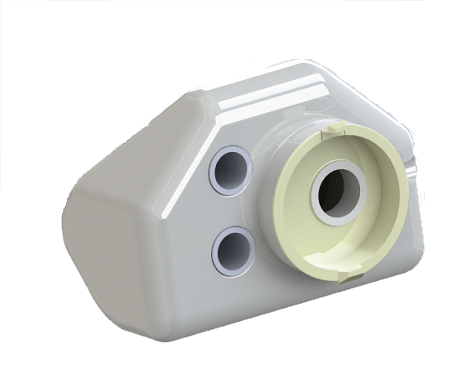

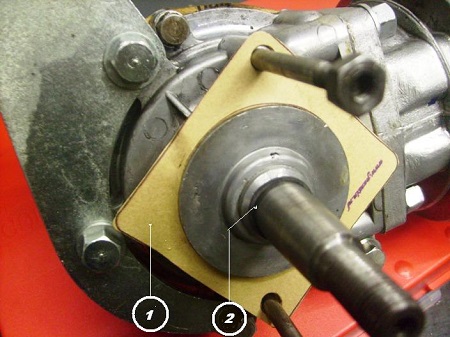

HUB BLOCS

In the hubs of our SP99, 99Z, SP98 and some other "heavy" models you will find a special construction of

the rear wheel's hub.

Dismounting of the wheel is possible, while the chain and chain wheel will stay in position.

This construction has also been applied for German Mopeds such as Zundapp.

For Zundapp there are rubber bushing available, but those are of a minor quality.

Frank Fr. had this problem and we found out that the Zundapp bushings were too soft.

You need rubber with a hardness of 80-90 degrees Shore.

For rubber this is pretty hard. Finally polyurethan was chosen.

Next problem for Frank was to process this raw material. Solution was again simple: apply a grinding tool.

The very first tests on the road were promising.

After this job was finished, we heard that in France hub rubber bushings are produced again.

During the Heerhugowaard fair the checked hardness was not very high. I would prefer the bushings made by Frank.

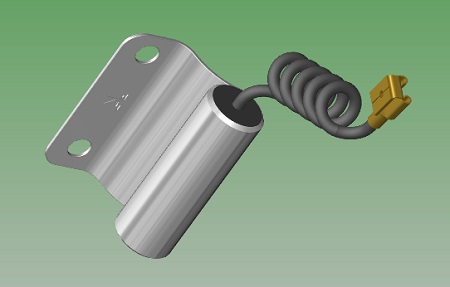

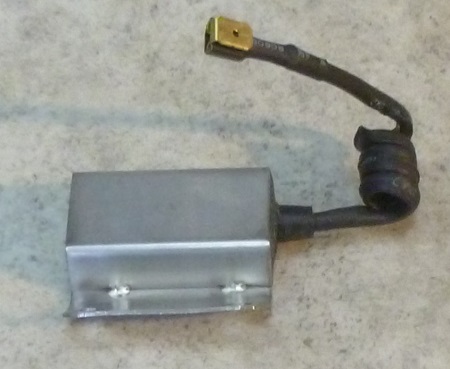

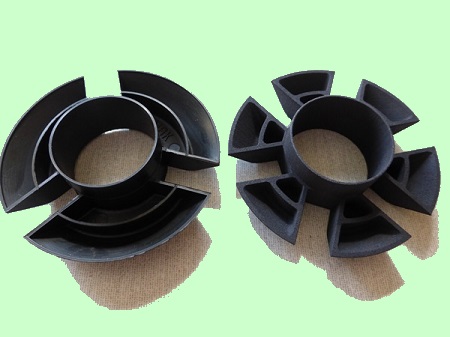

Lower picture

For an other project we had to make 4 new pins, because all were - with a lot of play - connected to the hub.

The assembly has been riveted at the hub.

In this case we could apply the original bushings from Motobécane, made of hard rubber.

|

|

|

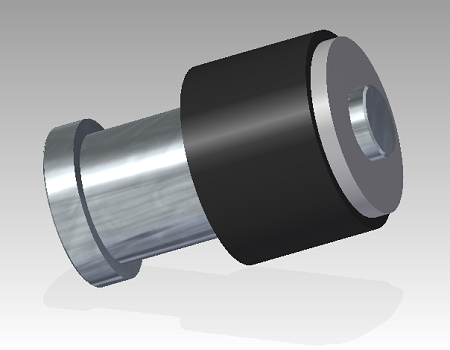

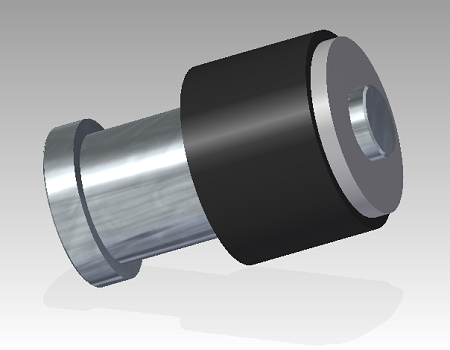

RINGS FOR CHAIN GUARD SCREWS

Black rings for the well-known chain guard screws are available

nowadays, but sometimes people you do not want to apply black rings.

So one day we made some white ones for a special project. The first ones

always will take some time, but after a while the rings can be produced

more efficiently.

|

|

|

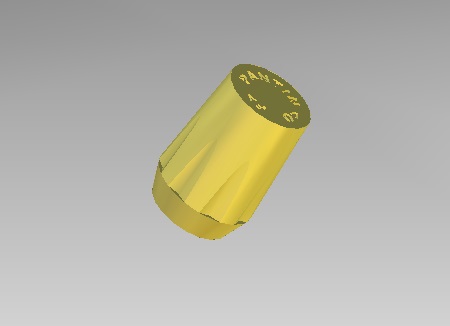

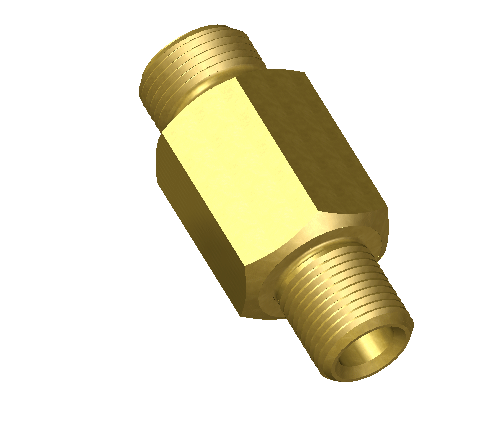

TAP FOR AV42 / ROBINET MOBYLETTE AV42

N O T A V A I L A B L E !

AV42/44 taps cannot be found easily.

Yes, some people offer those NOS-taps on www.ebay.fr - mostly in an excellent condition - , but the price is

quite high compared to the prices in the Netherlands or Belgium.

5 years ago however, we started a study for examining the possibilities to make some.

Main reason was the challenge to design, engineer and produce such a tap.

After we made and tested several prototypes, we recently produced some

and they were appointed to our stock for special projects.

Though this tap design has become smarter, it still takes too much time to produce them.

Perhaps we will pick up this project again in due time.

At this moment those taps are not available for resale.

Characteristics:

- All parts are made by PantinNL.

- All parts can be replaced easily.

- Reliable and strong construction.

- No vulnerable joints were applied.

|

|

|

TAP BG

Bob Moesker

Bob - an engineer from Zaandam in The Netherlands - worked out a method for

repairing a BG fuel tap.

Unfortunately Bob deceased some time ago and his tools and his tap-knowlegde had partly lost.

At Pantin we started a study to find a better way of dismantling and assembling new gaskets.

Thanks to special tools, better materials and a different approach, those taps can be repaired well!

However obtaining taps and spares is still far from easy.

Often many parts are no longer useable and then we cannot help owners of a BG with repairing their tap.

If your tap is just leaking, but looks usable at the outside, we may be able to help you.

Other solutions

Besides solution above there are more options. Applying a different tap with an intermediate piece is one of those.

Some people apply a hose tap. Not as it used to be, but as long as you can shut off your fuel supply for 100% it is better than a leaking tap.

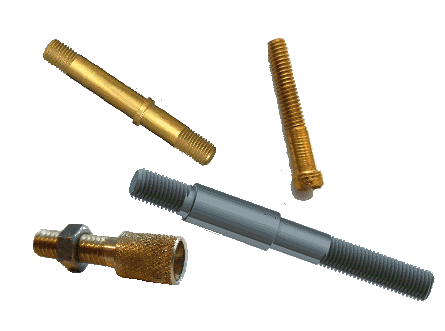

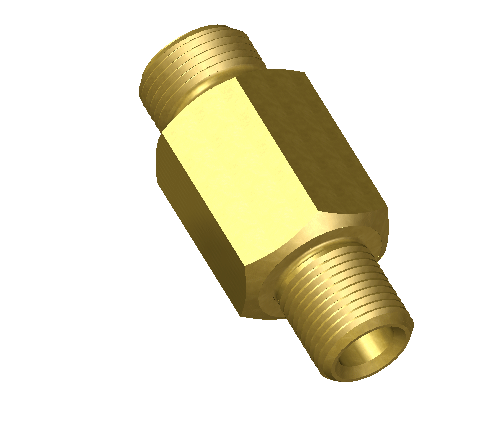

Intermediate piece example

When applying intermediate pieces, a world of new possibilities comes within reach.

Not just for the BG-tap, but for all taps. On the right a test example for a AV42-petrol tank.

The main problem for most people is: where can I buy the right intermediate piece?

We do not know, because the screw thread is not standard. Sizes such as: M14 x 1 and M10 x 1 are not common in the the plumbing industry.

The solution is simple: make it yourself on a lathe. We did and it works perfectly.

|

|

|

EXHAUST PIPE MODEL 99E AND 99Z

Some time ago we launched a plan for reproducing new 99 exhaust pipes, but people did not show much interest

Finally a small batch of just 6 pipes and corresponding swivels were made by Jan Elbers, who lives around here.

Future batches for the SP98 pipe is not likely, but when the stock runs out....it will not be excluded.

EXHAUST PIPE MODEL SP93 and AV92

This study has finished. The result is negative, because the available

tools did not meet the required purposes. Problem is the pipe diameter.

It changes on several spots thus making a simple construction

impossible.

The radius of the thick pipe is rather small. This means we will have to

search for another solution. To be continued....

|

|

|

SPROCKET FOR RELAY-BOX AV92, SP92, SP94TT, SP98 AND 99

Since we prefer small ones, we had to make those by ourselves.

At the old worn sprocket all teeth will be removed by way of grinding.

A new sprocket will adapted on a lathe and all will be welded.

If you want such a small sprocket do not ask us, but consult a professional company. We just like prototyping.

On the right you see a sprocket with 12 teeth, which is ready to be welded.

|

Special sprocket

|

|

AIRSAL RING

Airsal is still producing cylinders and pistons for mobylette and of

course for a lot of other marques.

We use the square 50-cc AV7 on our models, but some long exhausts will

give troubles like the exhaust of models SP98 and D52.

The copper ring, which seals the connection between exhaust pipe and

cylinder can be deformed too much and will be pressed to deep into the

cylinder barrel.

After a while the exhaust pipe is not sealed anymore and the large gland

nut will be loose.

We solved this problem by putting a thin bronze ring in front of the

copper washer. A big radius prevents extra turbulence of the outlet

gasses.

Thanks to this simple and cheap solution all problems have disappeared

now.

|

|

|

BRAKE PLUG

A brake plug is a casting in Zamac, which is fixed at the end of the handlebars

ZAMAC is an acronym for Zinc, Aluminium, Magnesium, and Copper alloy.

Casting Zamac is not so complicated. For this foundry process we have

use the lost wax casting method. This way of casting is very old: more

than 6000 years ago people used this kind of manufacturing.

After casting some machining is required, because the brake cable will

be guided by a bronze bushing, that also is threaded for fixing the plug

at the handlebars with a small screw.

Zamak is a weak material and a threaded hole is quickly damaged.

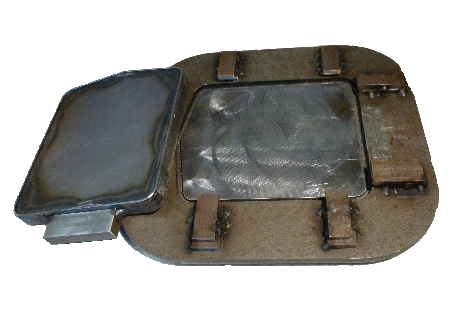

The picture in the middle shows the mould for making the wax model. This model was made of polyester resign.

The picture at the bottom shows some rough castings.

|

|