![]() In this part you may find answers to your questions.

In this part you may find answers to your questions.

IGNITION-SYSTEM

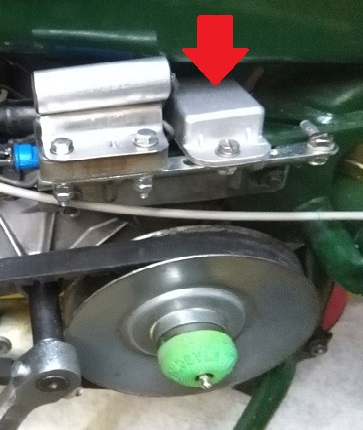

In the past most questions concerned ignition. Remind that the pressure of the mixture in a hot cylinder is higher and the spark meets more resistance. Anyway a common problem, but an affordable solution is shown in the publications that doesn't interfere withthe authentic looks of your old timers. |

Coil and capacitor hidden in front of the rear mud guard. |

HOW CAN I TEST A CONDENSATOR?

Lately somebody asked by way of our guestbook for a test method. Well, there several ways to test a condensator: Addendum 3: Disconnect the battery or battery charger and wait for one minute. Check by way of a led-light if the charge is able to light the led. If nothing happens turm the led and connect it the other way. Remind a led is a diode. Instead of a led you could use a multi-meter.

|  Coil and capacitor are being tested with a Prüfrex-tool.

| |

WHY NOT AN ELECTRONIC IGNITION SYSTEM?

People often ask why we don't apply electronic ignition systems, though there are sets for the AV7-engine available? Well, there several reasons why we don't: |

WHY DO MY BULBS BLOW?

|

The trouble mostly starts with the lighting coil that offers a current with a high tension of 40 Volts. |

A lot of space at the AV92/SP93 |

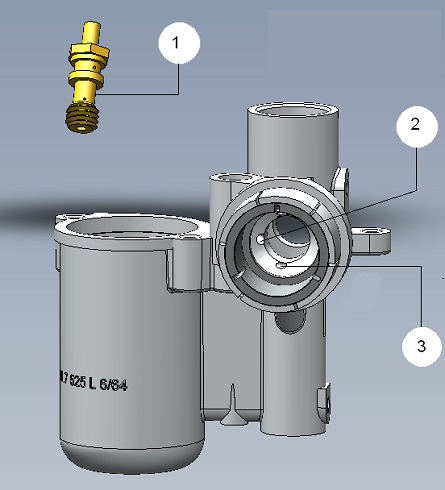

DISMANTLING DIMOBY CLUTCH

From time to time an experiencedmechanic is calling, because he is not able to dismount the centrifugalclutch. From time to time an experiencedmechanic is calling, because he is not able to dismount the centrifugalclutch.Let us see how we can fix it. Firstly you remove the hexagon nut and the grease nipple. Next you need an extractor,which has to be screwed into the cover of the clutch. An inner bolt pullsthe cover off the camshaft. If you cannot find an extractor contact me. |

Detail of Dimoby centrifugal clutch.

| The red washer has to be removed off the camshaft before you can see the second circlip ring. | Dismantling Dimoby clutch |

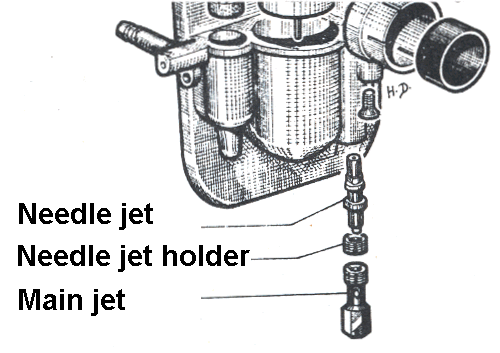

CLEANING CARBURETTOR AND NEEDLE JET

Carburetors can be very polluted. |  Examples of jets for a 12mm carburettor

Example of a threaded needle jet |

By coincidence we found a lot of different jets a long time ago. We still wonder about the great differences in geometry. |  Some examples of needle jets with holes for stationary speed. |

TSL: a great oil enhancer

TUNING & SUFFICIENT POWER

If so, then you can start thinking about improvements. Mostly your little bike will run fast enough now.Its design was not meant for high speeds. Frame, brakes, tyres and suspension are inadequate for use at high speeds. Our mission is not to ruin ancient engines by increasing their performance, but getting them on the road again according theiroriginal specifications.

Though they are old now, they should run like in their young days or even better, when improved sealing, ignition or lubrication additives have been applied.

Unfortunately many people complain that their engine is not running well after they have restored that engine "perfectly".The reality is - without any doubt - different. We always note many mechanical defects in vehicles. Transmissions malfunctioning because of worn chains, sprockets, chain wheels and bearings. Crankshafts, pistons and cylinders with too much clearance.

Ignition is an other source of failure. If the spark fails regularly then the performance is considerable lower.

The best and cheapest start for power enhancing is: make sure that the basics are good.

- All parts should be in a "pretty" mechanical condition.

- Strong ignition system.

- A cylinder with Nicasil lining as manufactured by Airsal .

- Better lubrication by using oil enhancing additives as TSL

Sometimes people use 66cc and 75cc cilindres, but are not aware of the fact that more power and higher speed means less safety on the road, moreover

this could give insurance problems in case of a major traffic accident.The famous French poet La Fontaine used to say: "Do not hurry, but leave on time!" We only can agree with that statement.

Top 12 of problems that influence factory speed

Several years ago these tyres were a problem, but suddenly some manufacturers started to produce these tyres again. A large number of different taps can be found on mobylette. Some are availabele from stock, while others cannot be repaired ; at least they say so. A hard to get sprocket and especially when you want to apply a small one (12 and 13 teeth). Special sprocket Everybody who wants to repair a mobylette will meet this problem: normal metric bolts and nuts will not fit.

It is not a matter of strange French thread, but it is just metric thread with a different pitch. The well-known screws for the engine side panels are an example.

They choose a long time ago not for standard M5x0.8 but instead of this for M5x0.9 (mm). This website will focus on technology for people all over the world.We will not exclude a lot of interested people for just a few that cannot understand English.Besides www.translate.google.com translates English to Spanish and French better than from Dutch to other languages. Actually this website was not special designed for smart phones,

in spite of the fact that many visitors are using a smart phone for web browsing.

There is no such list, where you can order parts at Pantin.

Public sharing of files for 3D prints and public sharing of specific process information is not our policy.

Failing is positive, when it leads to improvements.

TYRES FOR 21 INCH RIMS

There are several tyres fittingon the same 21 inch rim:

TAPS

At Pantin we are able to fix those taps.In chapter Creations - Parts-overhauled we show some solutions.

SPROCKET FOR SP93, AV92 AND SP94TT

Since we prefer small ones, we had to make those by ourselves.

If you want such a small sprocket do not ask us, but consult a professional company. We just like prototyping.

On the right you see a sprocket with 12 teeth, which is ready to be welded.

FRENCH THREAD

Why did they not choose for standard thread?

The only reason is a commercial one; as customer you cannot apply a cheap standard bolt or nut.

The fact that Motobécane often used bolts and nuts with a pitch of 1mm, is an advantage when you make the thread on a lathe. You do not have to change the pitch every time.

We found a pitch of 1mm at next threads: M7, M8, M10, M11, M12, M13, M14, M24, M26 and M46. This list, however, is not exhaustive.

Happily most taps and dies can be found on the net.

WHY ENGLISH AS MAIN LANGUAGE?

WHY IS THIS WEBSITE SO FAST ON SMART PHONES?

We simply love clean code and keep our images small. This website is less than about 15MB!; just 3 high resolution images of a camera.

WHERE CAN I FIND A PANTIN ORDER LIST?

Our stock of spares is limited and meant for our own projects and to help friends with their projects.

WHERE CAN I FIND 3D PRINT FILES?

Nevertheless we cooperate a lot with friends and third parties; exchanging special information is part of it.

When you want to design a special part and you need some help, you should ask us.

CRITICAL SUCCESS FACTORS FOR LONG RIDES IN FRANCE.

Some years ago during a trip to the south of France, we had chosen for the most basic way: riding on a mobylette and sleeping

in a tent at a camping site.

This choice will always lead to an extra burden for your mobylette.

In spite of all preparations we had to cancel this trip for several reasons.

Bottom problems, loosening of exhaust nut, navigation problems and most important time.

Getting at the event in time had become impossible...

A new approach was needed to prevent such problems in future.

Critical success factors of our last long rides are:

MODULE FAILURE ANALYSIS

In many manuals you can find information about the cause of engine troubles.

Nevertheless in reality it is often a hell of job to find the malfunctioning part(s).

It should be possible to build an interactive knowledge system, that will be able to locate possible failure(s).

Building a database system, that will contain entities like: cause, part failure, system failure, part and solution,

will not be enough for an intelligent expert system. The occurrences of failures can be irregular and different failures can occur at the same time.

Theoretically a system may malfunction, though all components are fine when checked in an equivalent system.

Lately we solved a lot of strange problems; finding the cause was hard, whereas the solution was mostly quite simple.

Nevertheless it is a nice challenge for next winter.

When a distribution will be available is hard to forecast.

So when you have problems read your manuals, visit forums and contact us when nobody can solve your problem.

DIFFERENT QUESTION?

info@pantin.nl

When you look at the drawing , you will see in front of and behind the red ring a so called "Seeger ring orcirclip ring ". Mostly people manage to remove the first ring and thinkthat the job has done. They are looking against the (in this drawing = red colored) washer, which covers the second circlip (Seeger) ring, and they are very surprised that they cannot remove the coupling housing.The red washer has to be removedwith a magnetic extractor or with two small pins. Because of the greasethis simple ring has been stuck on the second Seeger ring. Sometimesit helps when you shake the engine a bit.

When you look at the drawing , you will see in front of and behind the red ring a so called "Seeger ring orcirclip ring ". Mostly people manage to remove the first ring and thinkthat the job has done. They are looking against the (in this drawing = red colored) washer, which covers the second circlip (Seeger) ring, and they are very surprised that they cannot remove the coupling housing.The red washer has to be removedwith a magnetic extractor or with two small pins. Because of the greasethis simple ring has been stuck on the second Seeger ring. Sometimesit helps when you shake the engine a bit.